Free-machining brasses

Brass is a metal alloy made of copper and zinc.The presence of other elements in brass such as lead is often required to improve machinability.

The superior machinability of brass is ideal for producing parts that are used in a variety of applications including valves, fittings and electrical components.

The most commonly used, free-machining brass is UNS alloy C36000. In some applications such as potable water systems, federal and state regulations restrict the use of lead.

This may require the specification of low or lead-free brasses.

Some lead-free brasses rely on elements other than lead to improve machinability and other properties such as strength, hardness and corrosion resistance.

The importance of scrap

The entire economy of the brass industry is dependent on the economic recycling of surplus material, or scrap.Brass for extrusion and hot forging is normally made from a basic melt of scrap of similar composition adjusted as required to meet the specification before pouring.

The majority of brass scrap consumed by US rod mills takes the form of turnings produced from machining operations.

Screw machine houses typically return brass turnings directly to the mill as part of the original purchasing agreement.

This type of scrap is commonly referred to as primary scrap. Other sources of scrap include brass components that have reached the end of their service lives.

This type of scrap, called end-of-life, demolition, or secondary scrap, is typically purchased, sorted and distributed by scrap dealers

Scrap stream contamination

It is important to keep leaded brass scrap separate from scrap used to produce lead-free brasses which should not contain lead by definition.Even within lead-free scrap, strict segregation is needed to keep scrap containing certain elements such as silicon and bismuth separate.

These elements can irreversibly concentrate up over time in the metal stream and are impossible to remove from the melt with economic production technology.

The presence of any undesirable impurities can cause problems such as hot shortness which causes expensive failures during casting and hot extrusion.

Strict segregation of brass scrap is therefore essential to protect the viability and economic advantages of all brass products.

Segregation of primary scrap returns from screw machine houses is much easier to control as compared to segregation of secondary, end-of-life scrap which is rather difficult to control.

Protecting the viability of the brass scrap stream

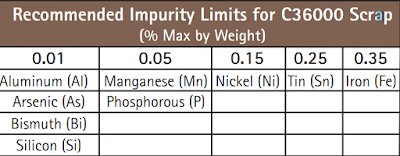

To proactively address this emerging issue, the major US brass rod producers have collectively established mutually agreedupon elemental impurity limits for C36000 scrap.The recommended limits shown in the table below are intended to help screw machine houses and scrap dealers understand the maximum impurity content that is acceptable for C36000 scrap.

Adhering to these guidelines will help avoid rejected batches and keep costs down for both suppliers and consumers of brass products and will secure the viability of the scrap stream for generations to come.

Comments

Post a Comment